Download our Poly Ash Comparison documents:

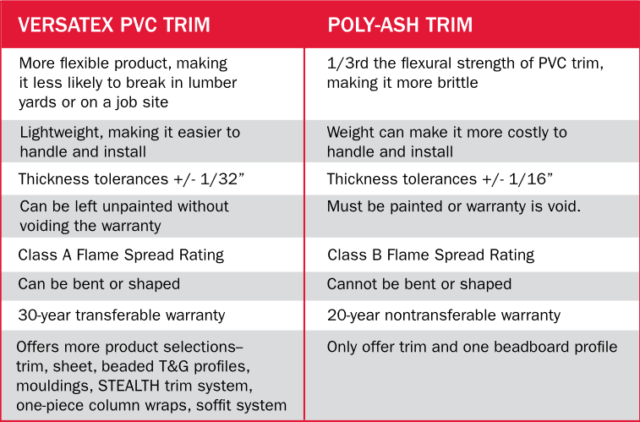

VERSATEX cellular PVC provides the workability and craftsmanship of a premium wood trim. Poly-ash trims, with many similar characteristics to fiber cement trims, are much heavier and rigid than VERSATEX, which creates issues with handling and installing VERSATEX is more flexible, making it less likely to break during shipping and handling, significantly reducing job-site waste. VERSATEX handles, routes, mills and installs like a fine piece of wood, yet due to its cellular PVC structure, is impervious to moisture and is UV stable. Unlike VERSATEX, poly-ash trims must be painted to protect their warranty.

EXPANSION/CONTRACTION? NO PROBLEM!

Everything moves, including poly-ash trim. To manage VERSATEX, simply follow our easy installation guidelines on the back of this document to ensure VERSATEX stays stable for years.

Movement occurs due to temperature fluctuations. This movement is restricted to the length of the product. The product will not swell or shrink like wood experiencing a moisture cycle. VERSATEX, like any PVC trim, will expand (lengthen) when it warms and contract (shrink) when it cools.

TIPS ON EXPANSION AND CONTRACTION

•Expansion and contraction is ONLY an issue on longer “runs” (rake, fascia, frieze) comprised of three or more 18′ boards (short lengths, around windows for example, can and should be built with tight joints).

•The more the product is mechanically fastened or bonded on longer runs, the less likely it will move.

•Screws restrict movement more than nails.

•As a rule, if you can bend the fastener in your fingers it is too thin (no wire or brad nails). 18 galv. and 16 galv. trim nails are not recommended.

•You can further restrict movement on longer runs by reducing on center fastening to 12″.

•Board movement is typically seen on walls with southern exposure, or areas where product is in direct sunlight.

•All joints in high traffic or visible areas should be glued tight. Expansion/ contraction joints should be placed in inconspicuous areas on long runs of trim.

•Allow VERSATEX to acclimate to outside temperature before installing. If possible install long runs of trim when boards and outside temperature are approximately 60-70°F

•Shiplap joints offer a superior joint, especially on long runs.

BEST PRACTICE TO CONTROL EXPANSION AND CONTRACTION AT BOARD JOINTS

Method #1: Leaving an Expansion Joint (High-Traffic Area)

1. Shiplap the boards at the joint, and glue the boards together with VERSATEX Weld-On #705 or another acceptable PVC cement.

2. When possible, apply construction adhesive to back side of boards. Liquid/ Nail Sub Floor Adhesives or Heavy Duty Construction adhesive works well when attaching a VERSATEX fascia board to a subfascia.

3. Double fasten on both sides of joint (remember screws work best). Use proper amount of fasteners based on width of boards.

4. On long runs of trim, allow for movement at the ends of the boards or at inconspicuous joints.

Method 2: Leaving an Expansion Joint

1. Based on temperature at time of installation (see chart below) create a gap between boards.

2. Follow proper fastening methods previously outlined.

3. Place UV resistant acrylic based or polymer based sealant in joint between boards (NPC Solar Seal #900 or equal is recommended).

4. Never completely fill joint with sealant. Leave room to compensate for joint closure.

FREQUENTLY ASKED QUESTIONS ABOUT EXPANSION AND CONTRACTION

WHAT ARE YOUR RECOMMENDATIONS FOR DEALING WITH EXPANSION AND CONTRACTION?

Use stainless steel annular shank nails or screws designed for wood trim and long enough to penetrate the solid substrate a minimum of 1 1/2″. Screws are better for limiting the thermal movement of the trim. Allow VERSATEX to acclimate to outside temperatures before installing. Bond VERSATEX joints to prevent separation. Be sure to allow adequate expansion and contraction space at the end of long runs of more than 3 boards. Decrease the on center spacing between fasteners to 12″ or less and bond

boards to substrate (ex. sub-fascia) when practical on long runs only. Leave a full 3/16″ gap when installing on a day where temperatures range from 35°F to 45°E Leave a gap just large enough to accept a bead of sealant or no gap at all (adhesive bond) when installing on a day when temperatures range from 80°F to 100°E Finally, shiplap joints are superior to scarf cut joints, especially on long runs.

WHAT TYPE OF FASTENERS ARE RECOMMENDED TO SECURE VERSATEX TO THE FRAME OF A BUILDING?

It depends on the temperature of the VERSATEX Trimboard at the time of installation, the length of the board, and how well you nail and bond the VERSATEX Trimboards to the substrate you are attaching it to. If you follow the above recommendations, your expansion or contraction will be limited to 1/8″ or less.